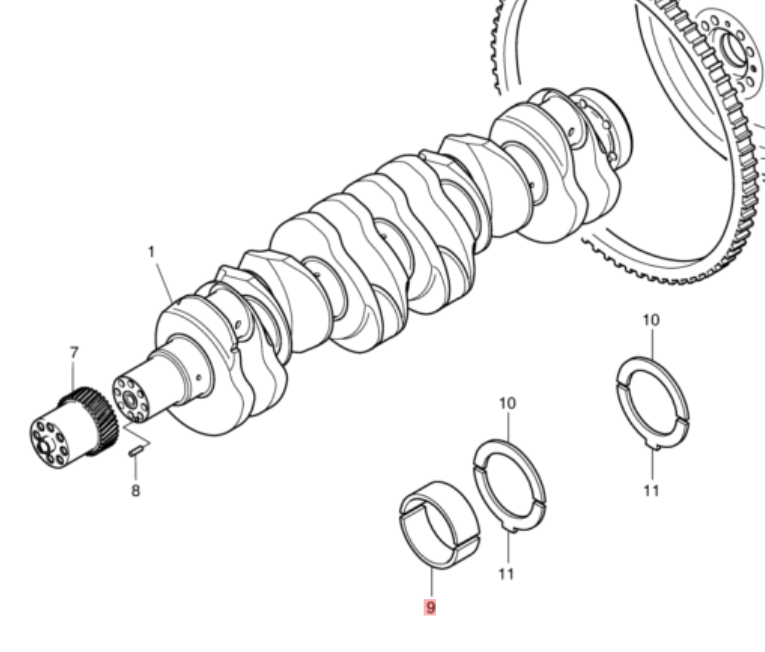

Crankshaft Bearings – Standard

Product NO.:140103-00075

Size / Dimension:100X50X35

Net Weight:0.213KG

The main function of the crankshaft bearing set in an excavator is to protect the journal and bearing holes, reduce friction and wear, and convert the gas forces transmitted from the piston-connecting rod assembly into torque for external output. Additionally, it is used to drive the engine’s valve mechanism and various auxiliary devices.

The crankshaft bearings, which include connecting rod bearings and main bearings, are crucial components of the excavator engine. Their primary functions are to protect the journal and bearing holes and to minimize friction and wear. These bearings convert the gas forces transmitted from the piston-connecting rod assembly into torque, thereby driving the engine’s valve mechanism and other auxiliary devices. The requirements for crankshaft bearings are very high, as they endure alternating loads and high-speed friction; therefore, the bearing materials must possess sufficient fatigue strength, low friction, and resistance to wear and corrosion.

The structure of crankshaft bearings typically consists of upper and lower bearing shells. Each bearing shell is made of a steel backing and a low-friction alloy layer, or a combination of steel backing, low-friction alloy layer, and a soft coating layer. This structure not only ensures that the bearing shells do not rotate, shift, or vibrate during operation but also facilitates heat dissipation. Additionally, the function of the crankshaft thrust bearing is to ensure the axial positioning of the crankshaft, preventing excessive axial movement that could affect the normal operation of the piston-connecting rod assembly and disrupt the correct timing of the valve and fuel injection in the diesel engine.

| Product NO. | Weight | Packaging unit |

| 140103-00075 | DH215-9E

DH220LC-9E DH225LC-9 D DX300LC DX300LC-3 |

EA |