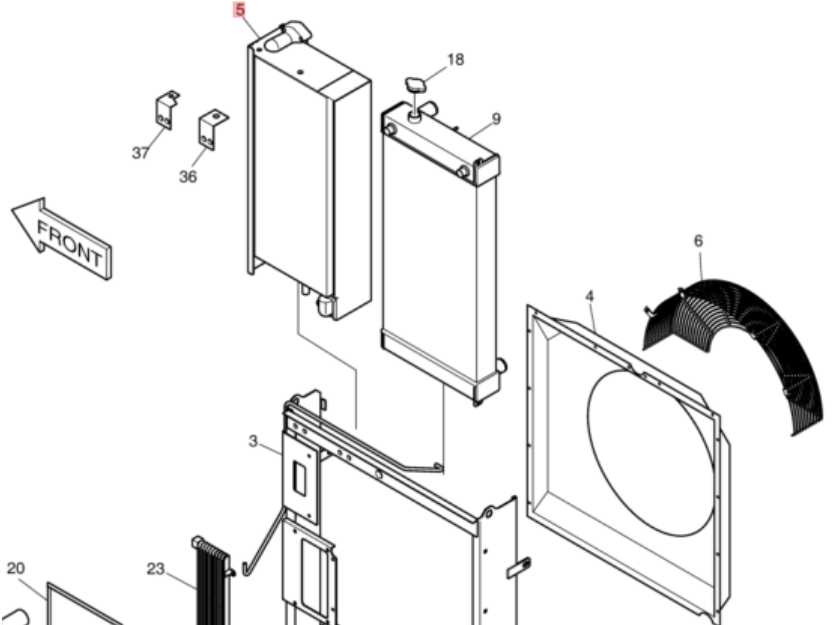

During the operation of excavators and other construction machinery, the hydraulic system and lubrication system work under sustained high pressure, generating a significant amount of heat, which leads to an increase in oil temperature. If the oil temperature is not controlled and reduced in a timely manner, it may cause aging and damage to the system’s sealing components. Additionally, the viscosity of the oil decreases as the temperature rises, affecting the lubrication effectiveness and potentially impacting the normal operation and safety of the equipment. Therefore, the oil cooler effectively reduces the oil temperature by facilitating heat exchange between two fluid media, ensuring the safe and reliable operation of excavators and other construction machinery.

There are various types of oil coolers, with the two main types being water-cooled and air-cooled. Water-cooled oil coolers use water as a medium to exchange heat with the oil, providing a good cooling effect and capable of lowering the oil temperature to a lower level. In contrast, air-cooled oil coolers reduce the oil temperature through air convection, making them suitable for different working environments and conditions. These coolers are widely used in various industries, including plastic machinery, construction machinery, mining machinery, automobiles, steel, wind power, and aerospace, ensuring the normal operation of these devices and extending their service life.

| Product NO. | Applicable models | Weight | Packaging unit |

| 400206-00661

400206-00661A |

DX215-5B

DX215-9C/DX215-9CN |

31.2 KG

31200 KG |

EA |

| 400206-00977A | DX360LC-3B

DX360LC-7B DX360LC-9C DX380-10 DX380-9C ACE DX380HD-10 DX380LC-9C DX380LC-9C ACE DX400LC-7B |

103 KG | EA |