The cover of the excavator oil filter serves to secure the filter and ensure overall sealing.

The oil filter, also known as the oil strainer, is primarily used to remove impurities such as dust, metal particles, carbon deposits, and soot from the engine oil to protect the engine. One of the main functions of the excavator filter element is to effectively filter out contaminants and pollutants that affect oil film thickness, and it is installed in the system’s pressure oil path and return oil path. The design of the oil filter cover has the following key functions:

Securing the filter: The design of the cover ensures that the filter is firmly mounted on the engine, preventing it from moving or falling off during operation.

Sealing function: The sealing capability of the cover ensures the integrity of the filter, preventing oil or other fluids from leaking, thereby maintaining the cleanliness and efficiency of the engine system.

In addition, the oil filter cover can effectively enhance the load-bearing capacity of the filter material. Typically, one side of the end cover is stamped to create a groove for placing the filter material’s end face and holding adhesive, while the other side is bonded with a rubber seal. This design serves to seal the filter material and the filter element channel. Not only does this enhance the performance of the filter, but it also ensures the long-term stable operation of the engine.

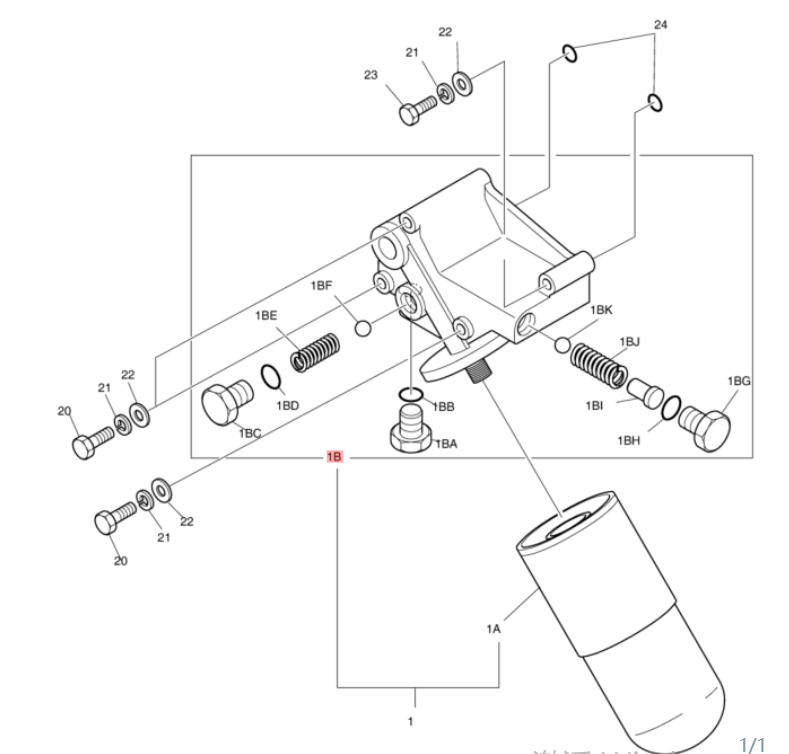

| Product NO. | Applicable models | Weight | Packaging unit |

| 400505-00082 | DX380LC

DX420LC DX500LC/DX500LCG DX340LCA |

5 KG | EA |