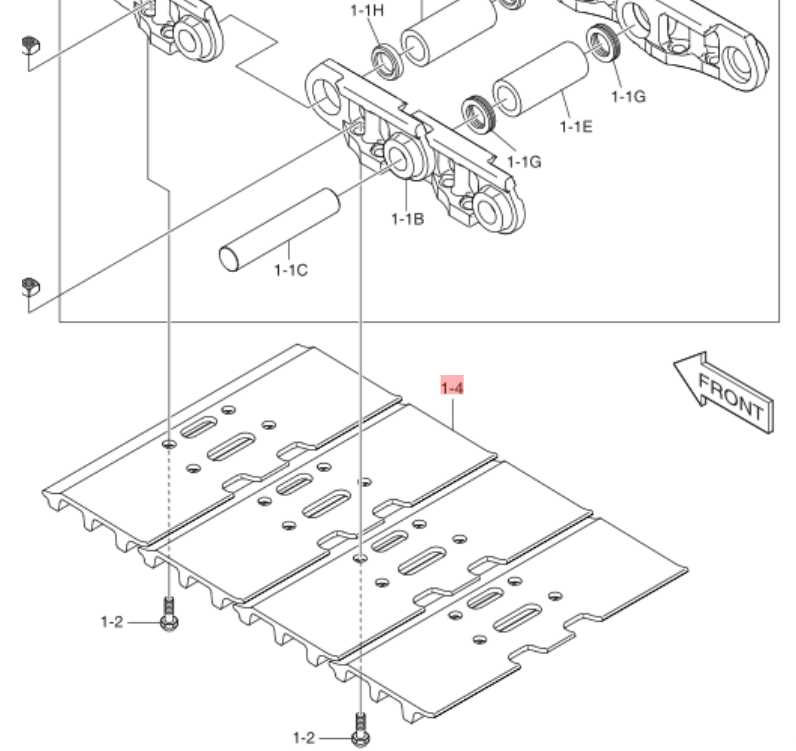

Track Shoes

Product NO.:200106-00262D1\200106-00148\200106-00877\200106-00262D1

200106-00262D1

Size/Dimension:600X220X40

Net Weight:16.61KG

200106-00262D1

Size/Dimension:600X220X40

Net Weight:16.61KG

The main function of the excavator track shoe is to distribute the weight of the excavator over a larger area by making contact with the ground, thereby reducing the pressure on the ground and enabling the excavator to walk steadily on various terrains such as loose soil, sand, and rocks.

Track shoes are a key component of the excavator’s undercarriage, and their design and manufacturing quality directly impact the performance and lifespan of the excavator. Track shoes are typically made from wear-resistant and high-strength materials, such as high-strength steel or alloy steel, with surfaces specially treated to enhance wear resistance and corrosion resistance. This design allows the track shoes to operate efficiently in various complex working environments while protecting the excavator from damage.

The ends of the track shoes have holes that engage with the drive wheels, and the middle section features guide teeth to align the track and prevent the track from coming off when the excavator is turning or tilting. The side of the track shoe that contacts the ground is equipped with reinforced anti-slip ribs to enhance the durability of the track shoe and the traction between the track and the ground. Track shoes are commonly used in excavators, bulldozers, crawler cranes, pavers, and other construction machinery.

Proper maintenance and care are crucial for extending the lifespan of track shoes and improving the overall performance of the excavator. This includes regularly checking the wear condition of the track shoes, timely replacing severely worn track shoes, keeping the track shoes clean to avoid the accumulation of dirt and debris, and performing regular lubrication to reduce friction and wear.

With the continuous advancement of technology and the development of excavator technology, the design and manufacturing of track shoes are also undergoing ongoing improvements and innovations. The application of new materials has made track shoes lighter, stronger, and more wear-resistant, while the structural design of the track shoes is continuously optimized to enhance the walking efficiency and stability of the excavator. As environmental awareness becomes more prevalent, the manufacturing process of track shoes is gradually becoming greener and more environmentally friendly.

| Product NO. | Applicable models | Weight | Packaging unit |

| 200106-00262D1 | DX190-3B/DX200-3B

DX200-9C (CN)/DX200-9C (CN) ACE DX205-10/DX205-10N DX210-7M DX215-10/DX215-10N DX215-5B DX215-9C ACE/DX215-9CN ACE DX215-9C/DX215-9CN DX220LC-9C DX220LC-9C ACE DX220LCA-2 / DX220A-2 DX225-10 DX225CD-9C DX225LC-10 DX225LC-9C DX230LC-9C DX245HD-10 DX245LC-9C ACE DX260LC DX260LC-9C DX270HD-10 DX270LC-9C ACE DX200A DX200A(S/N:1001~) DX200LC-7 DX210 / DX225LCB DX210-7 / DX210LC-7 / DX210NLC-7 DX220A / DX225LCA DX220AF DX220AF(S/N:1001~) DX220AF-7M DX220LC-5 DX220LC-5K(L) DX225LC-3 DX225LC-5 DX225LC-7 DX225LC-7M / DX225-7M DX225LC-7X DX225LCA-2 / DX200A-2 DX225LCA-7M / DX200A-7M DX235LC-5 DX235LC-7 / DX245NHD-7 DX240LC-7 DX240LC-7X DX255LC-3 DX255LC-5 DX255LC-7 DX225LC-3 DX255LC-3 |

16.61 KG | EA |

| 200106-00148 | DX300LC

DX300LC-7B DX300LC-9C DX300LCS DX305HD-10 DX305LC-9C ACE DX300LC DX300LC-3 DX300LC-3(S/N:1001~1511) DX300LC-3(S/N:1512~) DX300LC-5 DX300LC-5(S/N:1001~1057) DX300LC-5(S/N:1058~) DX300LC-5(S/N:20001~) DX300LC-5K(L) DX300LC-7 DX300LC-7K DX300LC-7M / DX320LC-7M DX300LCA DX300LCA-7M DX300LCE DX320LC-7 DX300LC-3 |

20.6 KG | EA |

| 200106-00877 | DX800HD-10

DX800LC-9C HX800AL HX800L |

45.26 KG | EA |

| 200106-00262D1 | DX190-3B/DX200-3B

DX200-9C (CN)/DX200-9C (CN) ACE DX205-10/DX205-10N DX210-7M DX215-10/DX215-10N DX215-5B DX215-9C ACE/DX215-9CN ACE DX215-9C/DX215-9CN DX220LC-9C DX220LC-9C ACE DX220LCA-2 / DX220A-2 DX225-10 DX225CD-9C DX225LC-10 DX225LC-9C DX230LC-9C DX245HD-10 DX245LC-9C ACE DX260LC DX260LC-9C DX270HD-10 DX270LC-9C ACE DX200A DX200A(S/N:1001~) DX200LC-7 DX210 / DX225LCB DX210-7 / DX210LC-7 / DX210NLC-7 DX220A / DX225LCA DX220AF DX220AF(S/N:1001~) DX220AF-7M DX220LC-5 DX220LC-5K(L) DX225LC-3 DX225LC-5 DX225LC-7 DX225LC-7M / DX225-7M DX225LC-7X DX225LCA-2 / DX200A-2 DX225LCA-7M / DX200A-7M DX235LC-5 DX235LC-7 / DX245NHD-7 DX240LC-7 DX240LC-7X DX255LC-3 DX255LC-5 DX255LC-7 DX225LC-3 DX255LC-3 |

16.61 KG | EA |