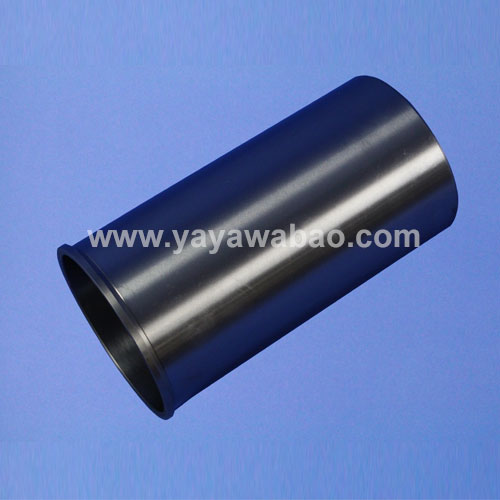

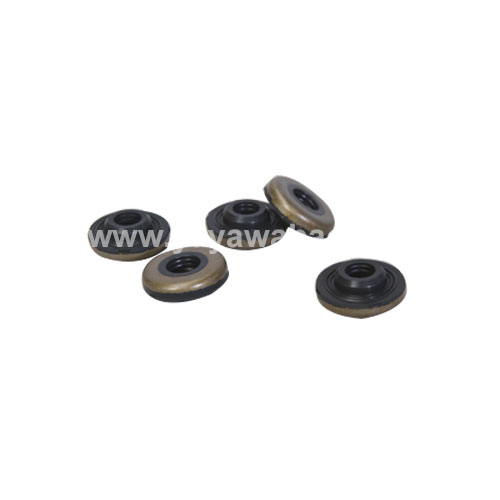

The turbocharged air pipe of the excavator is mainly responsible for introducing filtered and pre-treated air into the engine, especially in engines using turbocharging technology, it can also increase the intake pressure, increase the intake volume of the engine, thereby enhancing the power and torque of the engine. By optimizing the intake pressure and flow rate, the excavator can maintain stable power output under high load conditions, improving work efficiency. The structural characteristics of the turbocharged air pipe include the use of high-strength, lightweight materials, such as aluminum alloy, to reduce overall weight and enhance corrosion resistance. The inner wall of the pipe is smooth to reduce air flow resistance and improve intake efficiency. In terms of sealing, rubber seals or metal sealing rings are usually used at the connection between the turbocharged air pipe and the engine to ensure that the air does not leak and maintain stable intake pressure. Since the engine generates high temperatures during operation, the turbocharged air pipe needs to have good high temperature resistance to prevent material aging and performance degradation.

In terms of maintenance and care, regular cleaning of the turbocharged air pipe is crucial to maintain its performance. When cleaning, compressed air or special cleaning agents can be used, but care should be taken to avoid using overly aggressive or chemically strong cleaning agents to prevent damage to the pipe material. At the same time, regularly check the sealing at the connection between the turbocharged air pipe and the engine, and if the seals are found to be aging or damaged, they should be replaced in a timely manner to prevent air leakage. In daily use, avoid external impact or compression on the turbocharged air pipe to prevent damage to the pipe material or connections.

Although the turbocharged air pipe is just one component of the excavator’s intake system, its performance directly affects the overall performance and service life of the engine. If the turbocharged air pipe fails or malfunctions, it may result in insufficient engine intake, decreased power, increased fuel consumption, and even engine damage in severe cases. Therefore, understanding and mastering the basic knowledge and maintenance methods of the turbocharged air pipe is of great importance for the normal operation and service life of the excavator.

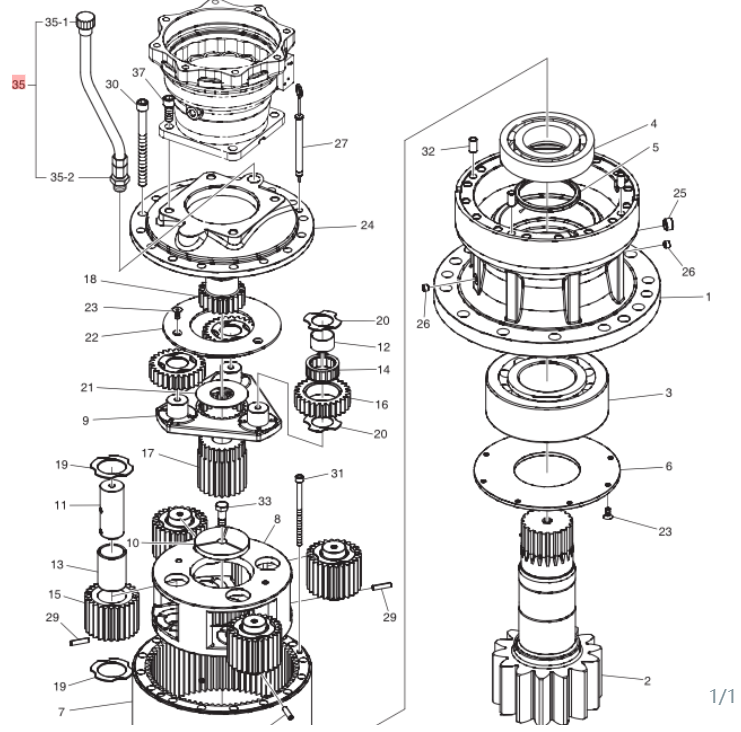

| Product NO. | Applicable models | Weight | Packaging unit |

| 420210-02081 | DX340LC-9C

DX380LC DX380LC-9C DX450LC-3B/DX450LC-9C DX340LC-5/DX350LC-5(S/N:10050~) DX380LC-3 DX380LC-3(OCEANIA) DX380LC-5 / DX400LC-5 DX420LC-3 DX420LC-5(S/N:10011~) DX420LCA |

0.8KG | EA |