Gear;Starter Ring

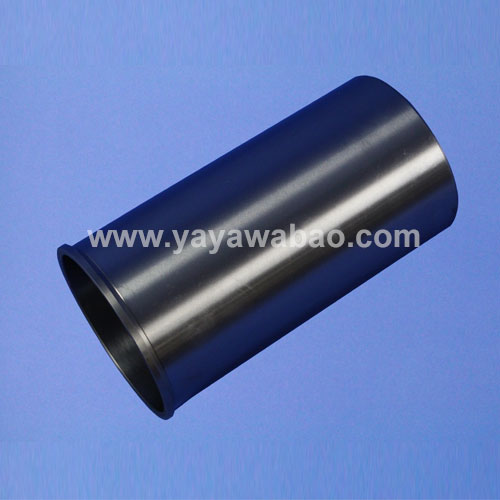

Product NO.:65.02310-0010A

65.02310-0010A

Size / Dimension:444X22

Net Weight:5.25KG

The main function of the gears in an excavator is to transmit power and motion, change rotational speed and torque, alter rotation direction, achieve long-distance transmission, provide smooth transmission and damping of vibrations, ensure precise transmission, and enable various forms of motion.

– Transmit power and motion: The fundamental role of gears is to transfer the power and motion from one gear to another through the meshing of two or more gears, driving the operation of the entire mechanical system.

– Change rotational speed and torque: By combining gears of different sizes, it is possible to increase or decrease rotational speed and modify torque. For example, a large gear driving a small gear can increase speed and reduce torque, while a small gear driving a large gear can decrease speed and increase torque.

– Alter rotation direction: By designing the gear teeth and installation method, it is possible to change the direction of rotation. For instance, two meshing bevel gears or helical gears can reverse the direction of rotation from the input shaft to the output shaft.

– Achieve long-distance transmission: In certain mechanical equipment, the need for long-distance transmission arises due to spatial layout or operational requirements. Gear transmission can achieve remote power transfer through the combination of intermediate shafts and multiple gears.

– Smooth transmission and damping of vibrations: Gear transmission is known for its smooth operation because the meshing of gear teeth can share the load and reduce impact. Additionally, by designing the gear teeth shape and material, damping of vibrations can be achieved to protect the mechanical equipment from damage.

– Precise transmission: Gear transmission offers high transmission accuracy, enabling precise control of speed ratios and positions, which is particularly crucial in machinery requiring high precision transmission.

– Enable various forms of motion: Through complex gear combinations and mechanism designs, a variety of intricate motion forms can be achieved, such as indexing motion and intermittent motion, making gear transmission widely applicable in automated equipment and complex mechanical systems.

Gears in excavators serve as crucial components in the travel and swing reduction gearbox, and their design and application directly impact the performance and efficiency of the excavator.

| Product NO. | Applicable models | Weight | Packaging unit |

| 65.02310-0010A | DX420LC-7

DX420LC-7K DX490LC-7 / DX530LC-7 DX490LC-7K / DX530LC-7K DX550LC-7 |

1.4 KG | EA |