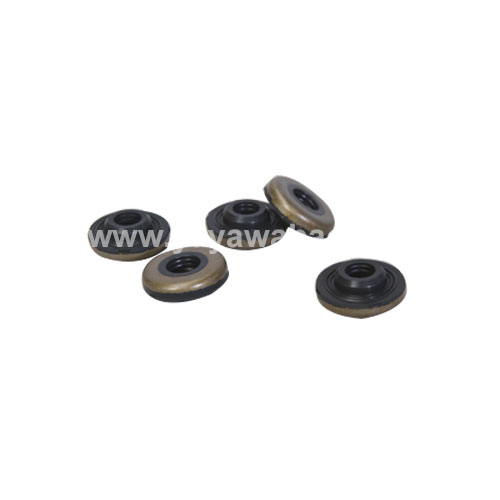

The main function of the excavator floating oil seal is to prevent lubricating oil leakage and ensure the normal operation of the excavator’s traveling mechanism.

The floating oil seal, also known as a mechanical end face seal, is a sealing device specifically designed to prevent oil or other fluids from leaking in machinery. It is commonly used in heavy machinery, such as construction equipment and industrial machinery, and can adapt to the axial and radial movements of the shaft without affecting the sealing effect, effectively preventing fluid leakage and extending the machine’s lifespan by reducing seal wear. The floating oil seal can withstand high temperatures and pressures, and can resist contaminants such as dust, dirt, and water, ensuring that it can maintain efficient operation in harsh working environments.

In the specific application of excavators, the floating oil seal is a key component of the excavator’s traveling mechanism, acting as a “shield” for the excavator, allowing it to maintain efficient operational capabilities in challenging work environments. Proper installation and maintenance of the floating oil seal are crucial to ensuring the sealing performance and extending the lifespan of the excavator. Incorrect installation of the floating oil seal may lead to lubricating oil leaks, affecting the performance and efficiency of the excavator.

Additionally, there are some techniques and considerations for the installation and maintenance of the floating oil seal. For example, during the installation process, checking for any breakage, cracks, or oil corrosion on the lip of the floating oil seal is important, and using specialized installation tools to prevent stretching or scratching damage to the seal lip. If damaged or worn sealing or mating rings are found, they should be promptly replaced to avoid costly repairs and downtime.

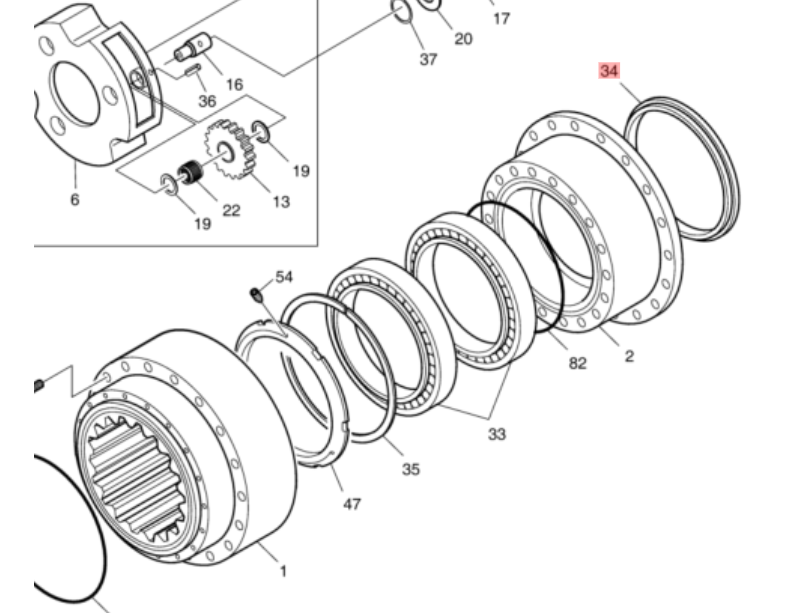

| Product NO. | Applicable models | Weight | Packaging unit |

| 180-00345A | DH300LC-7

DX300LC DX300LC-7B DX300LC-9C DX300LCS DX305HD-10 DX305LC-9C ACE DX340LC-9C DX345LC DX350LC DX360LC-3B DX360LC-7B DX360LC-9C DX380-10 DX380-9C ACE DX380HD-10 DX380LC DX380LC-9C DX380LC-9C ACE DX400LC-7B DX420LC DX450LC-3B/DX450LC-9C DX235LC-7 / DX245NHD-7 DX300LC DX300LC-3 DX300LC-3(S/N:1001~1511) DX300LC-3(S/N:1512~) DX300LC-5 DX300LC-5(S/N:1001~1057) DX300LC-5(S/N:1058~) DX300LC-5(S/N:20001~) DX300LC-5K(L) DX300LC-7 DX300LC-7K DX300LC-7M / DX320LC-7M DX300LCA DX300LCA-7M DX300LCE DX320LC-7 DX340LC DX340LC-3 / DX350LC-3 DX340LC-5/DX350LC-5(S/N:10001~10049) DX340LC-5 / DX350LC-5(S/N:10050~) DX340LC-5 / DX350LC-5(S/N:20001~) DX340LCA DX340LCA-K / DX360LCA-K(S/N:20001~) DX350LC DX350LC-7 DX350LC-7K DX350LCA / DX360LCA DX350LCR-7 DX360LC-7M DX360LCA(S/N:5950~) DX360LCA-7M DX380LC-3 DX380LC-3(OCEANIA) DX380LC-5 DX380LC-5 / DX400LC-5 DX380LC-5K(L) DX380LC-7 DX380LC-7K DX400LC-7 DX400LC-7M DX420LC-3 DX420LC-5(S/N:10001~10010) DX420LC-5(S/N:10011~) DX420LC-7 DX420LC-7K DX420LCA DX420LCA-K(S/N:20001~) DX450LC-7M DX450LCA-7M HX355ALCR SOLAR 300LC-7A SOLAR 340LC-V DX300LC-3 |

2.65 KG | EA |