The primary function of the excavator fuel filter sensor is to remove harmful impurities and water from the fuel system, protecting the engine’s normal operation, reducing wear, preventing blockages, and ultimately extending the engine’s lifespan.

The fuel filter sensor effectively protects the engine’s precision components from wear and blockages by filtering out harmful impurities and water from the fuel system. This protective measure is crucial for ensuring the stable operation of the engine because an excessive amount of impurities and water in the fuel system can lead to decreased engine performance and potential engine damage. Regularly replacing the fuel filter ensures the cleanliness of the fuel system, thereby prolonging the engine’s lifespan.

Furthermore, the fuel filter sensor also ensures the engine’s stable operation by monitoring the fuel injection quantity. If the fuel sensor malfunctions, it can lead to inaccurate fuel injection quantities, affecting the performance and efficiency of the excavator. Therefore, maintaining the fuel sensor in good condition is essential for the normal operation of the excavator.

In summary, the excavator fuel filter sensor protects the engine from damage by filtering out impurities and water, while also ensuring the engine’s stable operation by monitoring fuel injection quantities. This contributes to improving the overall performance and efficiency of the excavator.

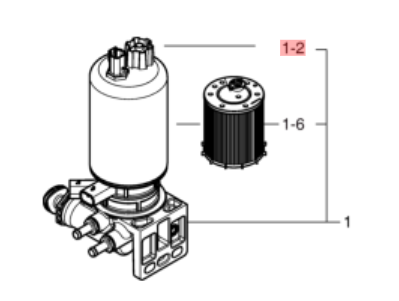

| Product NO. | Applicable models | Weight | Packaging unit |

| 410107-00037 | DX120

DX120-9C DX130-9C/DX130-9CN DX60-9C DX55-5 DX55-5K(L)(S/N:2066~) DX55MT-5 DX55MT-5K(L)(S/N:2066~) DX55W-5 DX55W-5K(L)(S/N:1701~) DX57W-5 E57W |

0.067KG | EA |