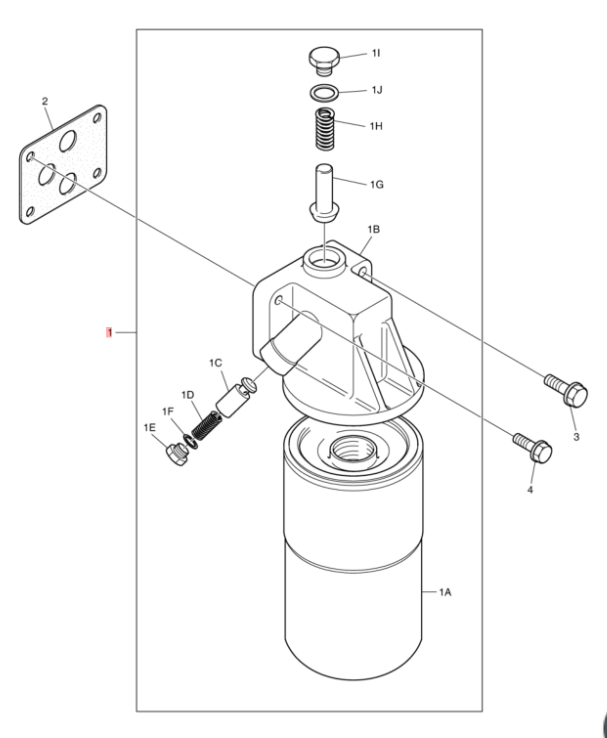

The main function of the excavator oil filter assembly is to remove impurities from the engine oil, such as dust, metal particles, carbon deposits, and soot, thereby protecting the engine from damage.

The oil filter, also known as the oil filter element, is an indispensable component in machinery such as excavators. Its primary functions include:

1. Filtering Impurities: The oil filter effectively removes various impurities from the engine oil, including dust, metal particles, carbon deposits, and soot. If these impurities are not removed in a timely manner, they can cause serious wear and damage to the internal components of the engine.

2. Protecting the Engine: By keeping the engine oil clean, the oil filter helps to extend the lifespan of internal engine parts, including the crankshaft, connecting rods, camshaft, turbocharger, and piston rings. This ensures that these moving parts receive proper lubrication, cooling, and cleaning, thereby reducing friction and wear.

3. Difference Between Full Flow and Bypass Filtration: Oil filters can be classified into full flow and bypass types. A full flow filter is connected in series between the oil pump and the main oil passage, filtering all the lubricating oil entering the main oil passage. In contrast, a bypass filter is connected in parallel with the main oil passage and only filters a portion of the lubricating oil sent by the oil pump.

4. Maintenance Cycle: The maintenance cycle for the oil filter should be regularly determined based on factors such as equipment usage frequency and working environment to ensure it continues to function effectively.

In summary, the excavator oil filter assembly plays a crucial role in protecting the engine, extending the lifespan of the equipment, and improving operational efficiency.

| Product NO. | Applicable models | Weight | Packaging unit

|

| 400404-00060A | DX300LCA

DX300LCA-7M |

3.4KG | EA |

| 400404-00022B | DX380LC

DX420LC DX500LC/DX500LCG |

6KG | EA |