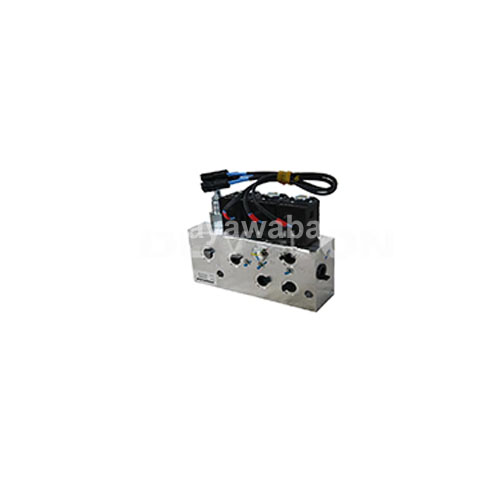

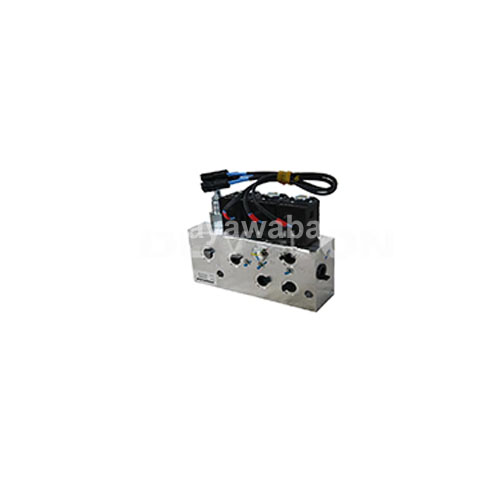

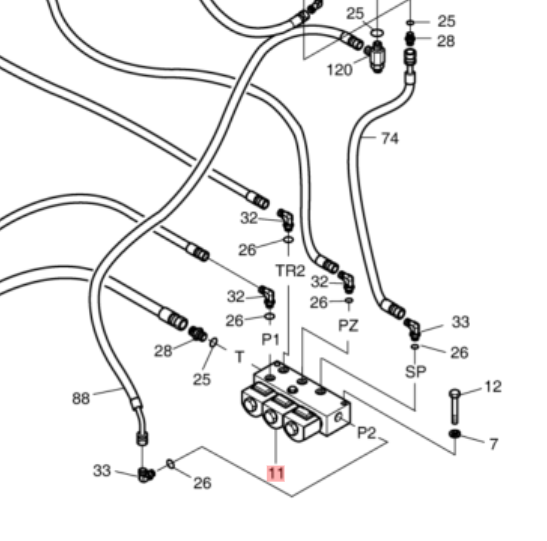

Pilot Solenoid Valve

Product NO.:K1002281\K10524-02

K1002281

Size/Dimension:150X132X55

Net Weight:2.947KG

The excavator’s solenoid valves are used to control the automation of the excavator’s fluids and are considered actuator components, not limited to just hydraulic or pneumatic systems. They are used in industrial control systems to adjust the direction, flow rate, speed, and other parameters of the media. Solenoid valves can be combined with different circuits to achieve the desired control, ensuring precision and flexibility in control. Solenoid valves play an important role in the hydraulic system of excavators. For example, there are generally two solenoid valves on the hydraulic pump, one being the TVC solenoid valve and the other the LS-EPC solenoid valve. The TVC solenoid valve is responsible for sensing signals from the engine speed sensor and adjusting the matching of engine power and hydraulic pump power. If the TVC solenoid valve is damaged, it may lead to issues such as engine stalling, lack of power, or difficulty starting.

The working principle of solenoid valves is to use an electromagnet to drive the valve core to control the direction of compressed air, thereby controlling the switch direction of pneumatic actuators. Depending on different requirements, solenoid valves can achieve functions such as two-way three-port and two-way five-port. The electromagnets used to operate solenoid valves are divided into AC and DC types. AC electromagnets typically have a voltage of 220 volts, providing greater starting force but lower reliability, while DC electromagnets typically have a voltage of 24 volts, offering reliable operation and longer lifespan but lower starting force. To improve the reliability and lifespan of solenoid directional valves, modern technology widely employs wet-type electromagnets. These electromagnets do not require sealing between the solenoid and spool push rod, eliminating friction, and the outer part of the electromagnetic coil is directly sealed with engineering plastic, ensuring insulation and aiding in heat dissipation, thereby enhancing reliability and lifespan.

| Product NO. | Applicable models | Weight | Packaging unit |

| K1002281 | DH215-7

DH215-9E DH220LC-7 DH220LC-9E SOLAR 220LC-6 |

2.947 KG | EA |

| K10524-02 | DH150W-7S

DH210W-7S DX210W-7B DX210W-9C (S/N:30001~) DX210W-9C/DX210W-9CN DX140W/ DX160W TIER-III DX140W ACE PLUS(S/N:8141~) DX140W TIER-III DX140WA DX190W DX190WA(T-2) DX210W DX210W-5B DX210WA DX210WA(T-2) |

7.5 KG | EA |