The main function of the plunger in an excavator is to provide a relatively stable and specific amount of fuel with pressure to the engine oil pump assembly within a unit of time.

The plunger in an excavator is an essential component of the hydraulic system, and its function is mainly reflected in the following aspects:

1.Provide Stable Fuel Supply**: The plunger ensures the engine receives a continuous and stable fuel supply by providing a relatively stable and specific amount of fuel with pressure to the engine oil pump assembly within a unit of time, thereby ensuring the normal operation of the excavator.

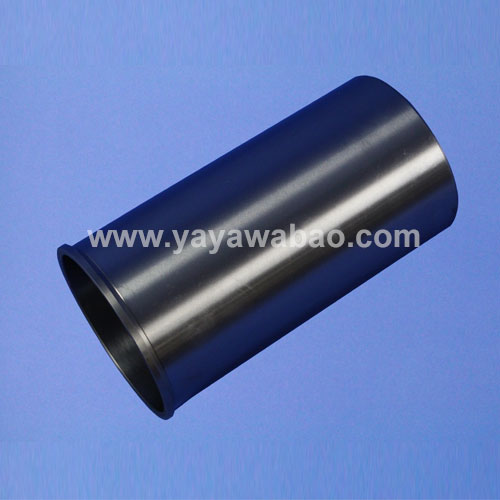

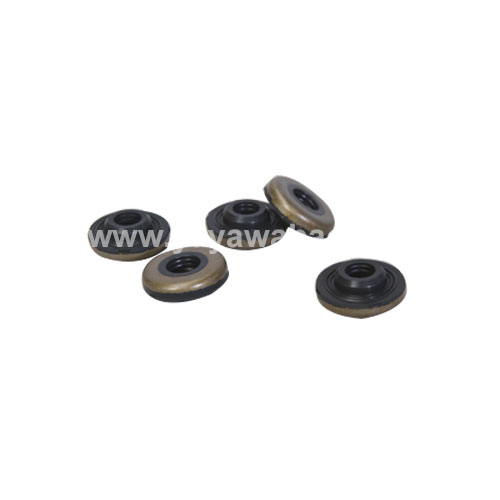

2.Material and Manufacturing Process**: Plungers are typically made of bearing steel and undergo processes such as heat treatment, vacuum quenching, sandblasting, phosphating, and oxidation treatment to ensure they have sufficient hardness and durability.

3.Accurate Fuel Metering**: The design and manufacturing precision of the plunger directly impact the accuracy of fuel metering, which is crucial for the performance and efficiency of the engine.

4.Difference from Gear Pumps**: Hydraulic pumps include gear pumps and plunger pumps. Gear pumps operate by the meshing of two gears, while plunger pumps achieve oil suction and discharge through the reciprocating movement of plungers in cylinders. Although both change volume to generate pressure on the liquid, plunger pumps are widely used in heavy machinery like excavators due to their more precise control and higher efficiency.

In conclusion, the specific design and manufacturing process of the plunger in an excavator ensure that the engine oil pump assembly receives a stable and precise fuel supply, thereby guaranteeing the performance and efficiency of the excavator.

| Product NO. | Applicable models |

| 409-00166 | DH150LC-7 |