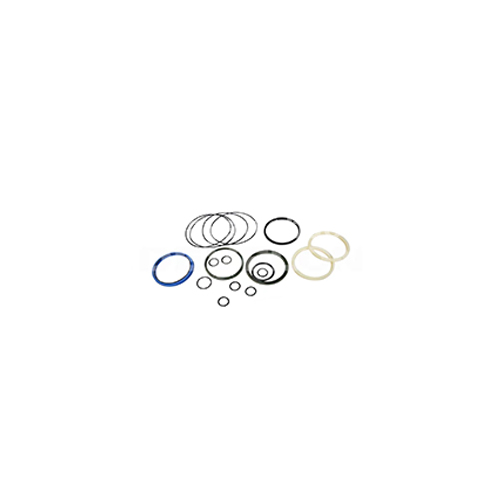

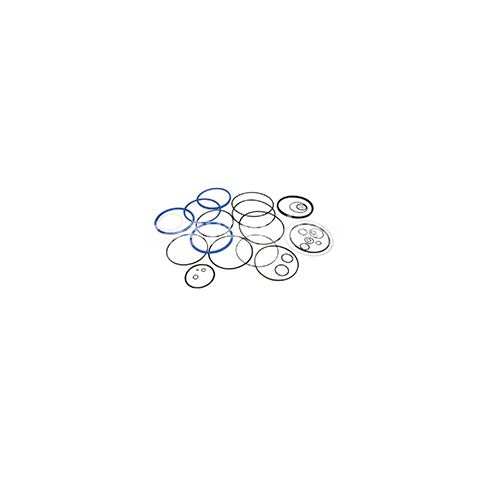

The primary function of the sealing components in an excavator is to prevent the leakage of working fluids, maintain the stable operation of the hydraulic system, extend the service life of the equipment, and prevent external contaminants and dirt from entering the hydraulic system.

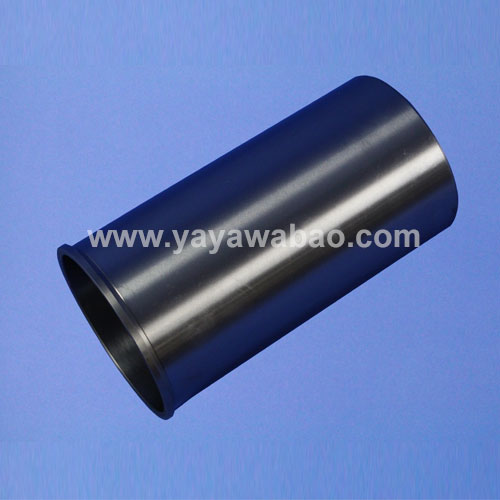

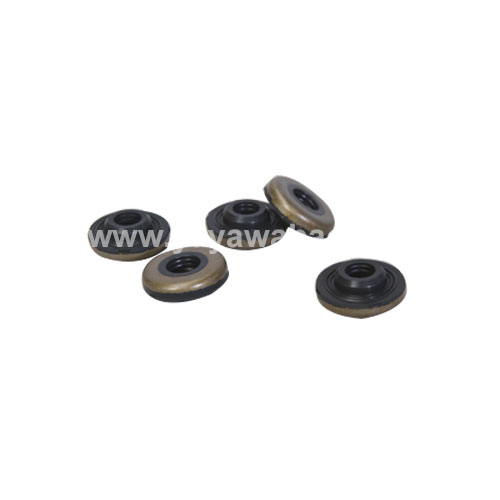

Sealing components in an excavator, such as sealing plugs and cylinder seals, are installed in the hydraulic cylinders, oil cylinders, and other interfaces that require fluid sealing. Their main functions include:

– Preventing Leakage: The integrity of sealing components directly affects the excavator’s work efficiency and operational safety. Any leakage can lead to resource wastage, environmental pollution, and mechanical failures.

– Maintaining System Stability: Good sealing performance ensures the stable operation of the excavator’s hydraulic system, preventing issues such as pressure drops or unresponsive operations caused by leaks.

– Extending Service Life: Regular inspection and replacement of sealing components can effectively prevent wear and failures in the hydraulic system due to seal failure, thereby extending the excavator’s service life.

– Preventing External Contaminants and Dirt Ingress: Sealing components help keep external contaminants and dirt out of the hydraulic system, thus prolonging the overall lifespan of the system.

Additionally, the design and material selection of the excavator’s sealing components are crucial. For example, piston seals made from high-quality industrial sealing products, such as those from Hudi®, feature contamination immersion capabilities to prevent damage to seals caused by external substances mixing with the oil inside the cylinder. Support rings possess high pressure-bearing capacity, eliminating metal-to-metal contact between the piston and cylinder body, providing high lateral load-bearing capability, absorbing shocks, and increasing contact area to avoid scratching the cylinder body. These design features and material choices work together to ensure the effectiveness and durability of the excavator’s sealing components.

| Product NO. | Applicable models |

| 401107-02100 | HB70 |