The primary function of urea in excavators is to treat exhaust emissions and reduce pollution generated by diesel engines.

Urea used in construction machinery, such as excavators, is also known as diesel exhaust fluid (DEF) or AUS32 (according to the GB29518-2013 standard). Its main purpose is to treat exhaust gases and minimize atmospheric pollution. The use of this urea solution became necessary as national emission standards for road machinery have become increasingly stringent, aimed at addressing the air pollution caused by diesel engines. Whether it is the Euro III, Euro IV, Euro V, or the upcoming Euro VI emission standards, all emphasize the importance of reducing pollution, and the addition of urea is a key method to achieve this goal.

Specifically for excavators and other construction machinery, the addition of urea depends on the engine’s after-treatment system, particularly the need for the Selective Catalytic Reduction (SCR) technology. The SCR system works by injecting a urea-water solution to neutralize nitrogen oxides (NOx) present in the diesel engine’s emissions, thereby reducing the discharge of these harmful substances and meeting environmental standards. Therefore, whether urea needs to be added and the amount to be added are determined based on the engine’s specific configuration and environmental requirements.

In summary, the role of urea in excavators is to reduce nitrogen oxides in diesel engine emissions through SCR technology, thereby lowering environmental pollution and achieving goals of environmental protection and sustainable development.

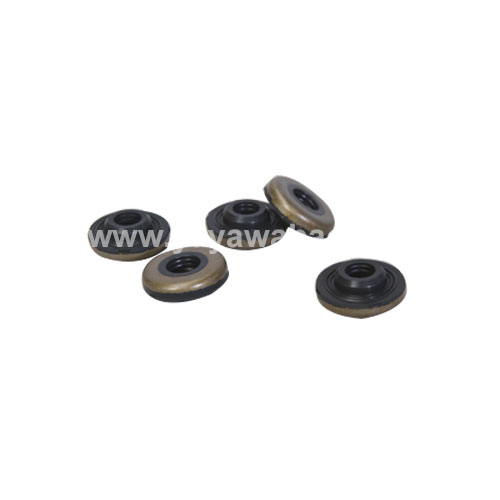

| Product NO. | Applicable models |

| 500141-00014 | National IV model |